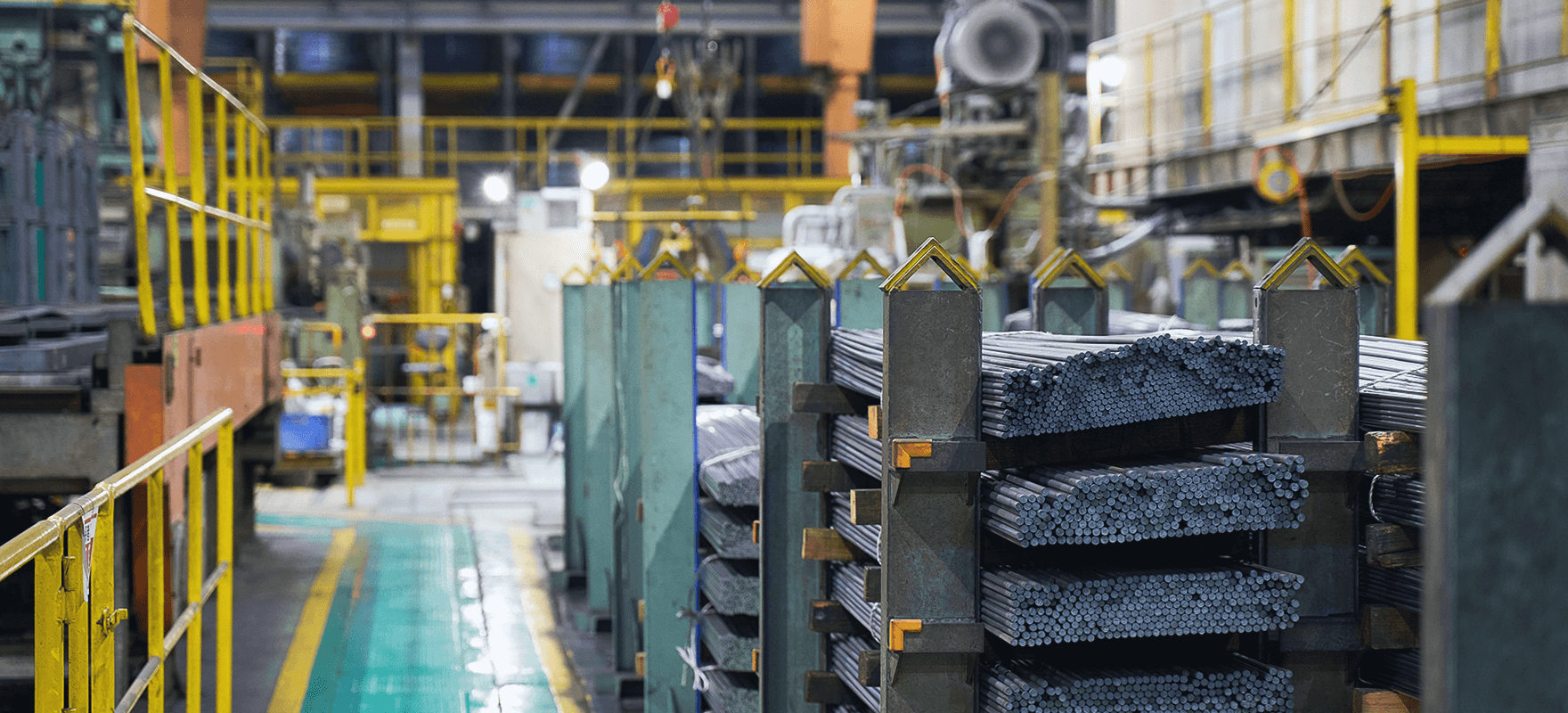

We provide custom products that fully cater to customers' requests.

Our special steel materials are manufactured to be completely customized. We select the dimensions, surface roughness, and other characteristics in accordance with customers' requests.

In addition, based on the knowhow we have accumulated through our experience, we can propose solutions to your issues that use new types of steels or treatment methods.

Our strengths in special steel materials

We hold the top share in Japan for engine valve heat-resistant steel and soft-magnetic stainless steel. We also sell our steel widely overseas. In particular, in 1960 Tohoku Steel became the first company in the world to develop soft-magnetic stainless steel. We carry a wide lineup for various usages to meet customer needs. We promote labor-saving automated operation for delivery and production at our plants in order to achieve shorter delivery times and appropriate costs.

Testing / Inspection system

We were the first special steel manufacturer in Japan to receive ISO/TS16949 certification (which is superseded by IATF) to manufacture soft-magnetic stainless steel for automobiles (cold drawn bars and drawn wires) and heat-resistant steel for automobiles (cold drawn bars and drawn bars). In this way, we maintain a quality assurance system that gives our customers a sense of security.

To test and inspect steel materials, we use strictly calibrated testing and inspection equipment in order to confirm that product characteristics (e.g., hardness, tension, and magnetic properties) meet customers' requests.

We use eddy current and ultrasonic testing methods to inspect 100% of many of our products so as to ensure the soundness of both their surfaces and internal components.

To test and inspect steel materials, we use strictly calibrated testing and inspection equipment in order to confirm that product characteristics (e.g., hardness, tension, and magnetic properties) meet customers' requests.

We use eddy current and ultrasonic testing methods to inspect 100% of many of our products so as to ensure the soundness of both their surfaces and internal components.